Bin picking

Bin picking refers to an automated process in manufacturing and logistics in which robots remove parts from a container (the so-called "bin").

This technology is mainly used in industry to increase production efficiency by replacing the manual removal of single components, thus saving time and costs.

The automated process is also used in the pick and pack process, which is essential for the fast and precise selection and packaging of products. By using modern robotics in combination with robot vision, these systems can even recognize parts that are difficult to grip, which significantly increases flexibility when handling different workpieces.

Operation mode of bin picking systems

In bin picking, a robot uses a combination of image processing, sensors, artificial intelligence and a gripper to identify and grab the objects in the bin.

Detection and localization of parts

The first phase of a bin picking system begins with the precise detection of the objects in the bin. This is done using sophisticated vision systems and 3D cameras that enable detailed analysis of the bin. These technologies scan the workpieces in the bin and create a 3D dot cloud that serves as the basis for further processing.

Using the model information generated, the system calculates the optimum grip in the bin so that the robot can remove the desired part precisely without unintentionally moving or damaging other objects.

A decisive advantage of this phase is the use of artificial intelligence (AI) and machine learning. These technologies enable the robot to determine the exact position of each part, even in confusing arrangements.

By continuously improving the system, the robot can also deal efficiently with complex and chaotic containers. This not only reduces shadowing (the problem where parts are not detected due to their position or orientation), but also ensures that each part is accurately identified and correctly picked.

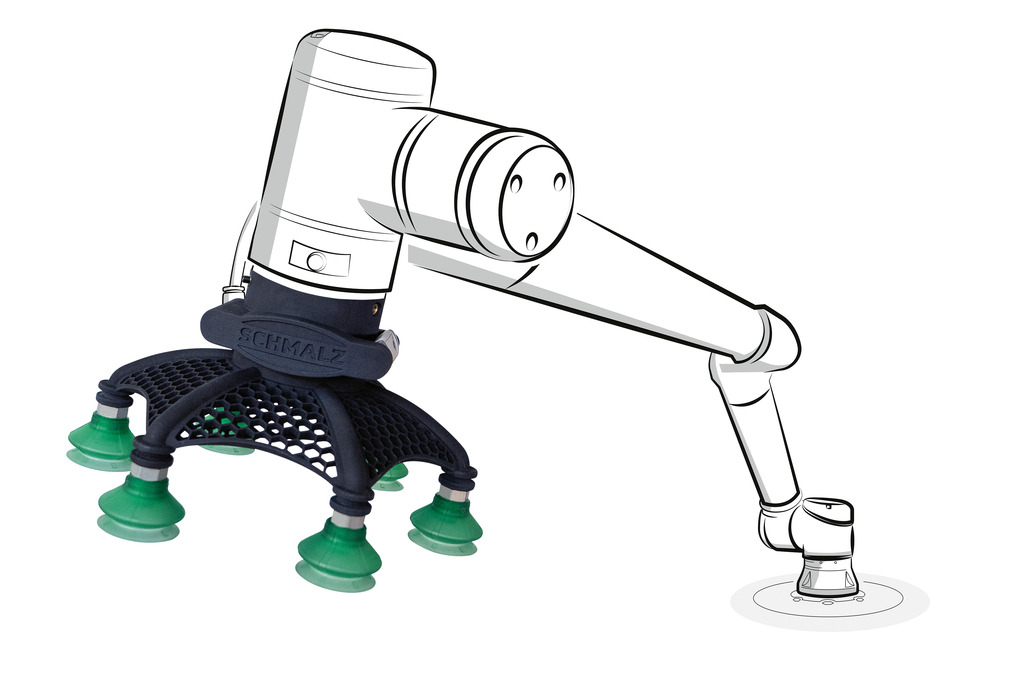

Gripping parts with vacuum technology

As soon as the position of the workpieces is known, vacuum technology comes into play. End-of-arm tooling (EOAT) with vacuum suction cups lift the workpieces out of the bin. These suction cups use vacuum to grip the objects safely and firmly without damaging them.

The flexibility of vacuum technology makes it possible to grip a wide variety of shapes and materials, from delicate workpieces to heavy components.

Transportation and placement

Once the workpiece has been removed, it is transported to the next processing or production step.

The robot can either place the workpieces in a specific sequence or according to the respective production requirement at the desired location or deposit them in a target container. This ensures smooth and efficient integration into the overall production process.

Optimization through AI and machine learning

Modern bin picking systems are circuitried with algorithms that allow the system to continuously improve.

Machine learning enables the robot to learn from previous experience and optimize its picking strategies, resulting in higher efficiency, a lower error rate and faster adaptation to new workpieces or varying conditions.

Advantages of bin picking systems

By using vacuum technology and image processing, bin picking systems are able to precisely grip and place workpieces. These systems can handle a variety of different objects, regardless of their complexity or geometry.

The automated removal process not only reduces human error, but also increases production speed, leading to a significant increase in efficiency.

Another advantage of this technology is that it takes the strain off employees, as repetitive, physically strenuous activities such as manual gripping of objects are taken over.

This promotes ergonomics in the workplace by reducing physical stress for employees and making the working environment safer at the same time.

Applications

Bin picking has applications in numerous industries, including the automotive industry, electronics manufacturing, the food industry and logistics.

In the automotive industry, for example, bin picking is used to automatically remove and further process workpieces such as screws, seals and other components.

In the food industry, the technology helps to precisely handle loose packaging or products such as fruit and vegetables.

Related terms

Further information

FAQ - Robotics - Cobots & lightweight robots

Find answers to questions about automated processes with cobots and vacuum grippers, and how to select your vacuum gripper and generator.

Vacuum Technology for Robotics

Robotics solutions from Schmalz are characterized by maximum precision, safety and process control in the gripping process.