Pick and place

Pick and place is a key technology in robotics in which robots pick up objects (pick) and place them in a specific location (place).

This automated handling technology is used in various industries to speed up processes, minimize errors and increase efficiency.

Design and operation mode of a pick and place robot

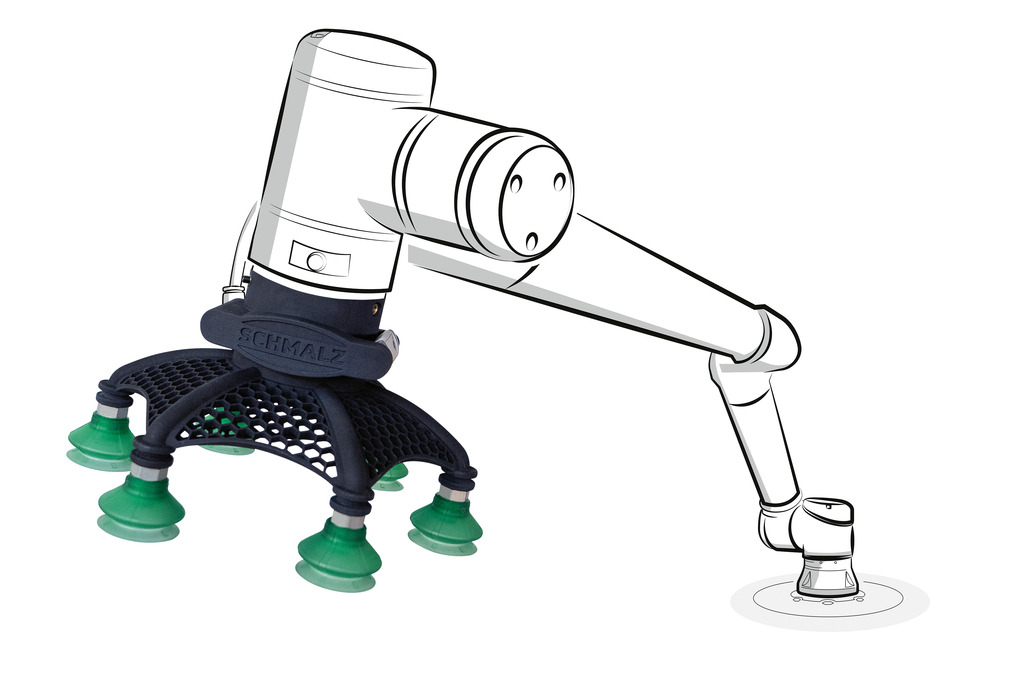

A pick-and-place robot is an industrial or collaborative robot (cobot) that is equipped with an EOAT (end-of-arm tooling) such as grippers or suction cups to handle objects precisely.

These robots are part of a comprehensive pick and place system consisting of a robot arm, sensors, a control unit and specialized software.

With the help of AI, image processing and integrated measurement technology, the systems detect workpieces, localize their position and transport them efficiently. The software plays a central role in optimizing the motion sequences and integrating the various components.

Depending on the application, pick and place systems can be combined with conveyor belts, palletizing systems or automated guided vehicles (AGVs) to further improve automated processes.

Technologies for different shapes, colors and textures

Pick-and-place robots are available in various sizes and shapes to meet the requirements of different applications.

While compact models work with high speed and precision for lightweight objects, larger variants are designed to move heavier workpieces safely. The choice of the right system depends on factors such as space availability, cycle rates and the nature of the objects to be handled.

Different technologies are used to safely grip different workpieces. Suitable gripping mechanisms are selected depending on the surface, texture and material properties.

Advanced 3D image processing enables the robots to recognize objects precisely, determine their position and move them optimally.

Applications in automation: from production to order picking

Pick-and-place robots play a central role in numerous automated processes and make a significant contribution to increasing efficiency in various industries.

They perform tasks such as sorting, palletizing, commissioning and the loading and unloading of machines and have become an integral part of modern manufacturing, logistics and the electronics industry.

In industry, they are indispensable for loading production systems, transporting raw materials and removing finished products from conveyor belts. In the automotive and food industries in particular, they are used to sort and pack goods quickly and precisely.

Thanks to AI-supported recognition, they can classify objects by weight, color or shape and prepare them for palletizing or depalletizing processes.

They are also essential in the electronics industry, especially when assembling printed-circuit boards. Thanks to their high precision, they place even the smallest components without errors and thus ensure reliable production.

Advantages of pick and place

Pick and place systems increase efficiency by reducing working time and speeding up production processes. Thanks to their high speed, they move large quantities of workpieces precisely and reliably.

In addition to increasing productivity, they also improve ergonomics in the workplace. They take over monotonous and physically demanding tasks, relieve employees and reduce health risks.

Their robust design makes them ideal for demanding industrial environments, while their flexibility allows them to be used in a wide range of industries - from electronics manufacturing to the food industry.

What's more, their space-saving design means they can be easily integrated even in tight production areas.

Related terms

Further information

Vacuum Technology for Robotics

Robotics solutions from Schmalz are characterized by maximum precision, safety and process control in the gripping process.

FAQ - Robotics - Cobots & lightweight robots

Find answers to questions about automated processes with cobots and vacuum grippers, and how to select your vacuum gripper and generator.