The new system is designed to reduce the workload on our specialists and increase the degree of automation.∼ Rainer Plöckinger, Foreman Interior Doors at the Kopfing location

Automated Door Handling With Vacuum Suction Spider

Josko, a renowned manufacturer of windows and doors, has worked with Schmalz to develop a highly automated solution for the efficient handling of heavy door panels. Thanks to an innovative suction spider and fully automatic robot integration, up to 80 door panels can be processed per day. This innovative solution reduces the strain on employees, increases the degree of automation and improves process reliability.

Characteristics of the success story

| Industry | Wood |

|---|---|

| Workpiece | Door leaves |

| Product group | Suction Spiders |

| Type of handling | Automated handling |

With Schmalz

80

door leaves

per day

The Customer: Josko Fenster und Türen GmbH

The door and window expert Josko was founded in 1960 as a one-man carpentry. In 2022, Josko generated a turnover of 215 million euros with over 1,000 employees. At its headquarters in Kopfing im Innkreis, Upper Austria, Josko today produces wood, plastics/aluminum and aluminum windows, house and interior doors on 39,000 square meters.

The Challenge

Before the Schmalz solution was introduced, it was a challenge for Josko employees to move the heavy interior door panles. The door panels, which weighed up to 100 kilograms, could not be handled by one person alone, and handling them with two people was physically too strenuous. Although Josko already had manual handling solutions in place to handle this heavy work, there were no spare parts available for the ageing turning device on the sanding machine, so Josko was looking for an overall solution to reduce the workload and increase the level of automation in production at the same time.

Schmalz's Solution

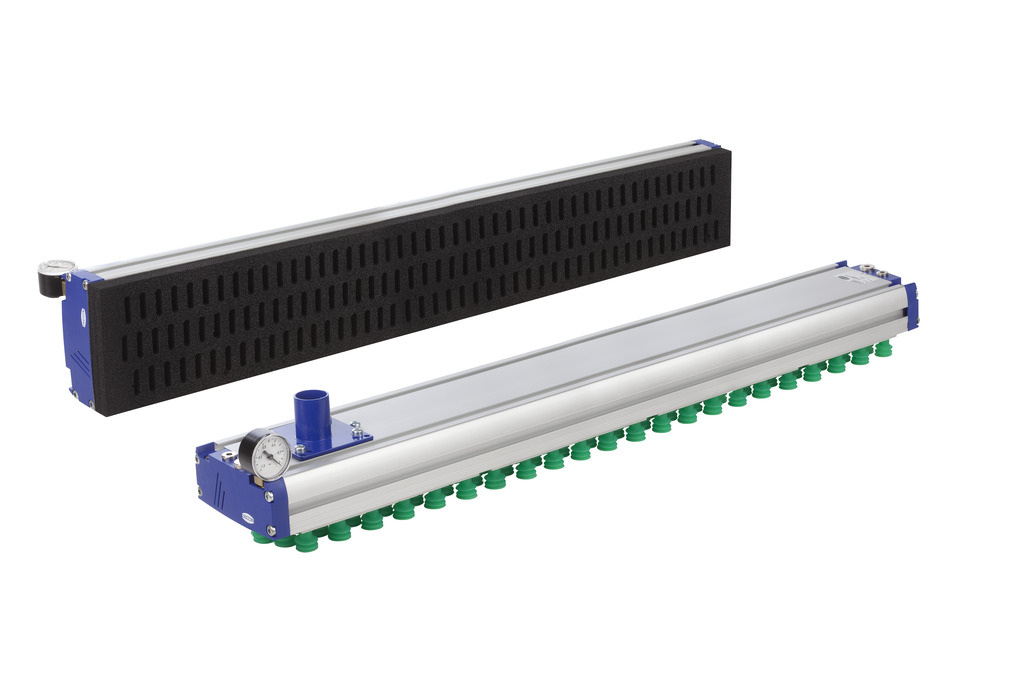

Instead of the old turning device on the sanding machine, Josko has introduced a new system consisting of two KUKA robots and the WEBER KSF sanding machine. The first robot picks up a door blank from the stack and places it on a conveyor belt in front of the sanding machine. The door leaf is fed through the machine to calibrate and sand the surface. The second robot then picks up the processed blank and places it on a rack. The first robot picks it up again, turns the door leaf and takes it back to the sanding machine to process the other half. The robots are circuitried with SPZ suction spiders from Schmalz, which ensure a safe grip of the door leaves. These suction spiders are specially tailored to Josko's requirements and are designed to provide optimum gripping surfaces for the door paneld while being light enough to enable fast movements. The suction spiders are based on the FMP-S gripping system with sealing foam. This gripping system is particularly suitable for heavy and rough workpieces and the sealing foam ensures a safe seal and a firm grip without damaging the workpiece. Vacuum generation takes place via a connector to the compressed air network and is controlled by valves. Thanks to the integrated system monitoring and sensor technology, the suction spiders operate with absolute process reliability. With the gripping solution from Schmalz, around 70 to 80 door panels are moved per day in an eight-hour shift, without the employees having to perform strenuous activities such as moving the heavy elements. The individual dimensions of the door panels can be easily selected via a display, which eliminates the need for manual programming and reduces potential sources of error. Overall, the Schmalz solution enables Josko to process the door panels efficiently and ergonomically, leading to an increase in productivity and employee satisfaction.

The suction spider holds door panels up to three meters in length and up to 100 kilograms in weight.

The handling solution works fully automatically in conjunction with the KUKA robot.

The sanding machine smoothes between 70 and 80 door panels per day on the front and back.

Thanks to the modular principle, the suction spider can be adapted to individual requirements.