Printed Circuit Board Assembly: process steps and applications

As in the case of PCB manufacture, Schmalz offers solutions for a number of different process steps. Schmalz distinguishes between the handling (automation) and the use of vacuum technology during a process step (process vacuum). The following table provides an overview of some of the most important process steps:

| Process step | Description | Vacuum handling (automation) | Process vacuum |

|---|---|---|---|

| 1 | PCB handling | ✓ | |

| 2 | Automated optical inspection (AOI) | ✓ | ✓ |

| 3 | Application of soldering paste | ||

| 4 | Assembly | ✓ | ✓ |

| 5 | Reflow soldering | ||

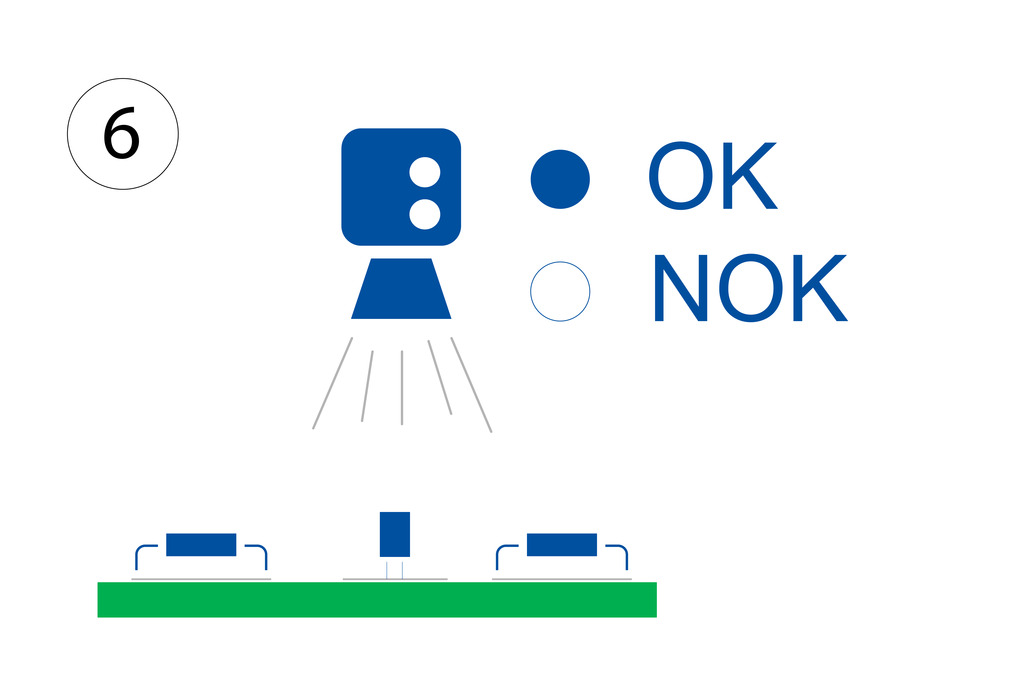

| 6 | AOI | ✓ | ✓ |

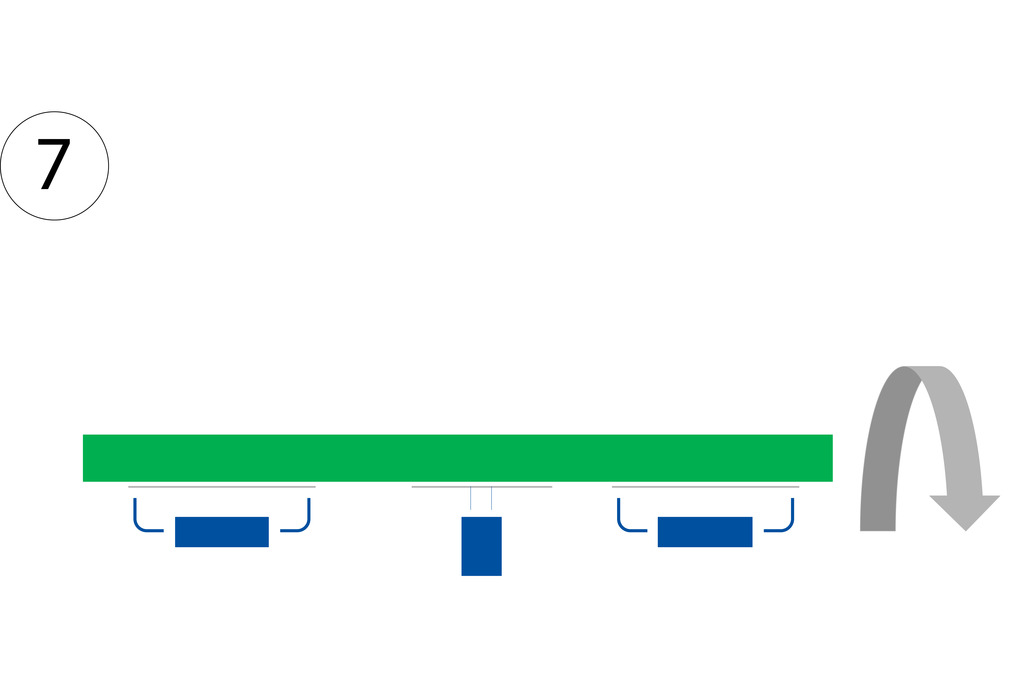

| 7 | Rotation | ✓ | ✓ |

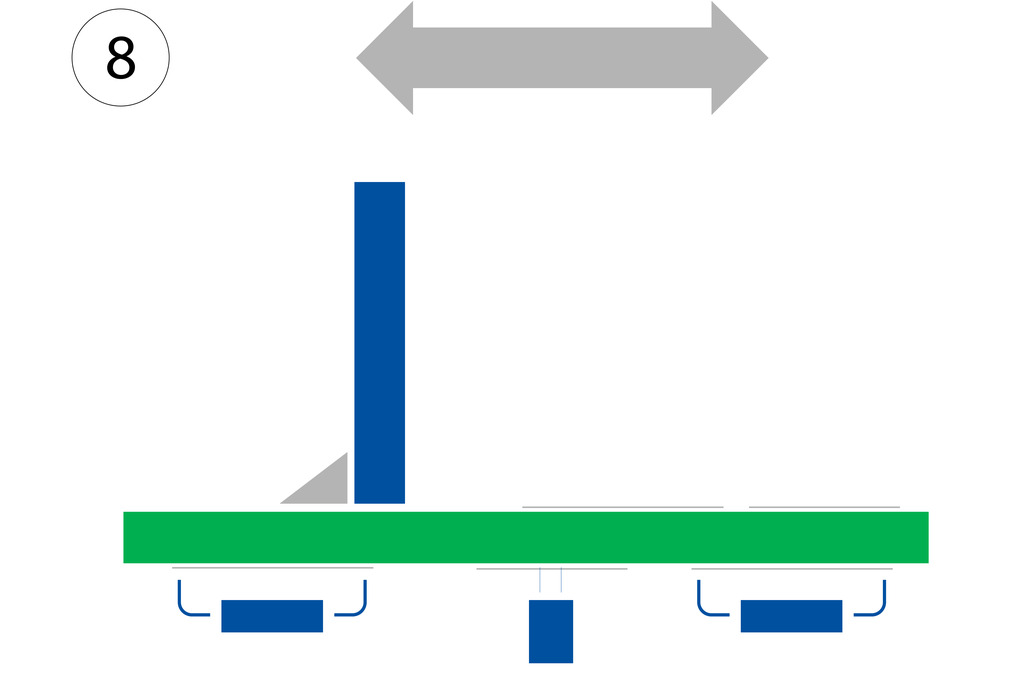

| 8 | Application of soldering paste | ||

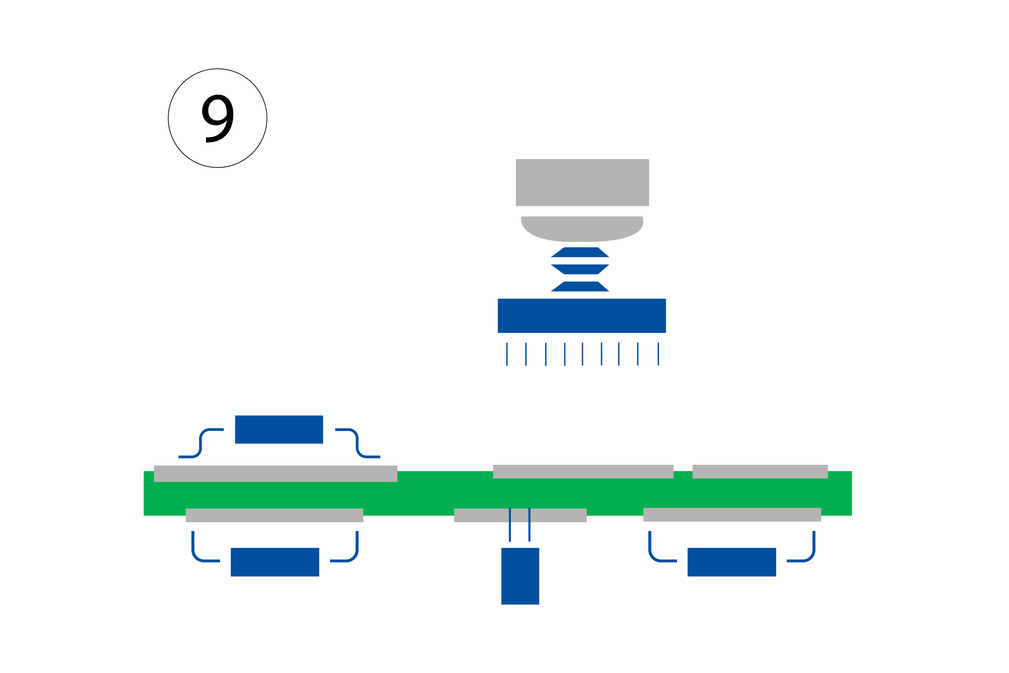

| 9 | Assembly | ✓ | ✓ |

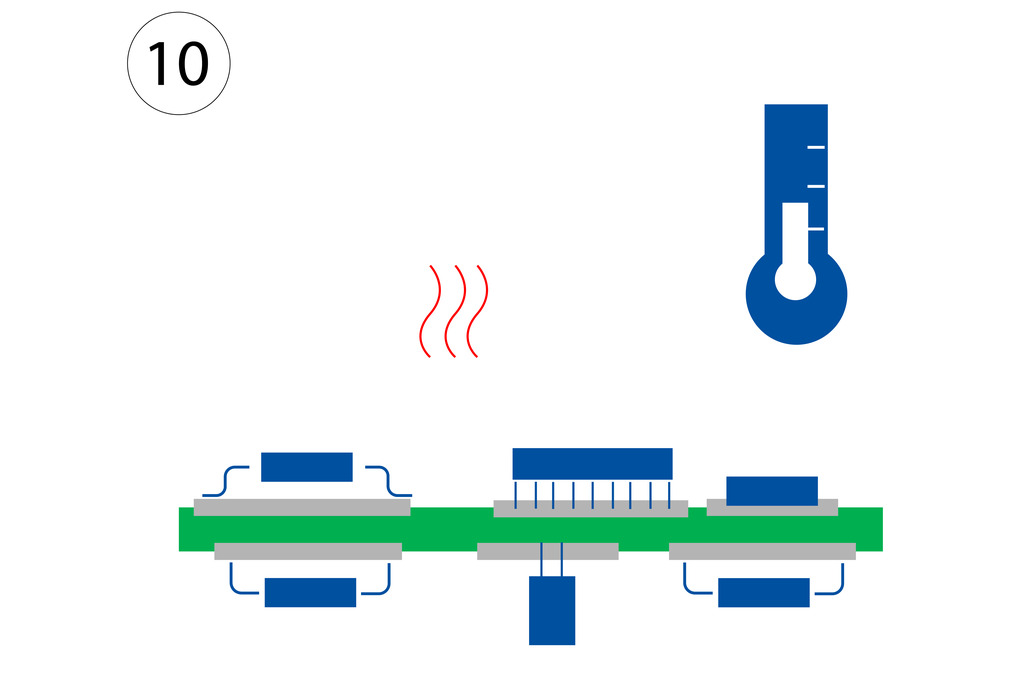

| 10 | Reflow soldering | ||

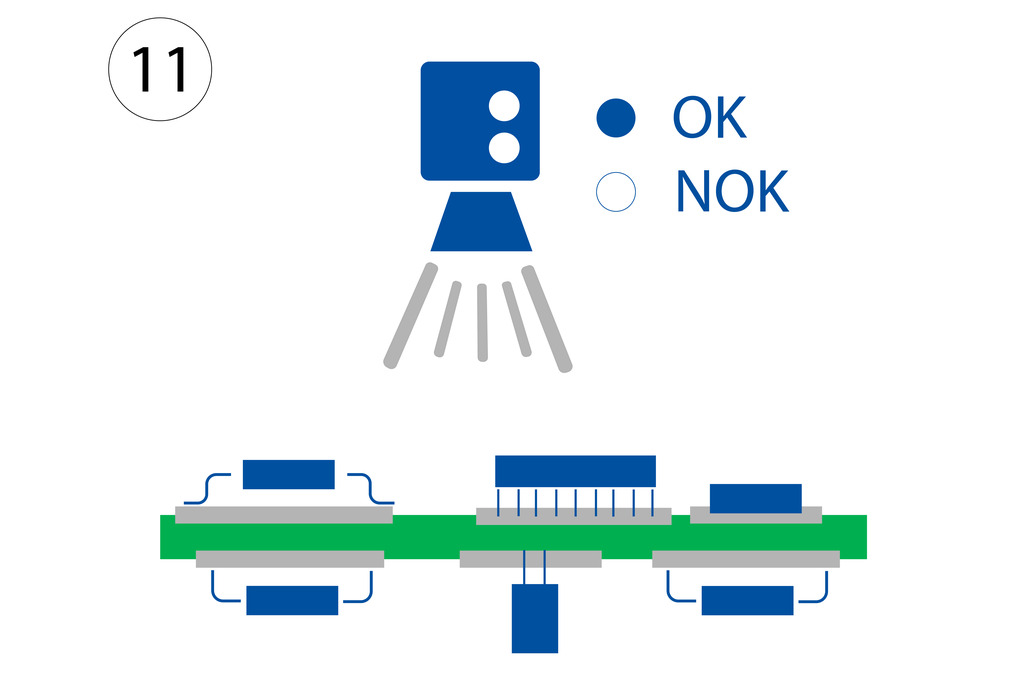

| 11 | AOI | ✓ | ✓ |

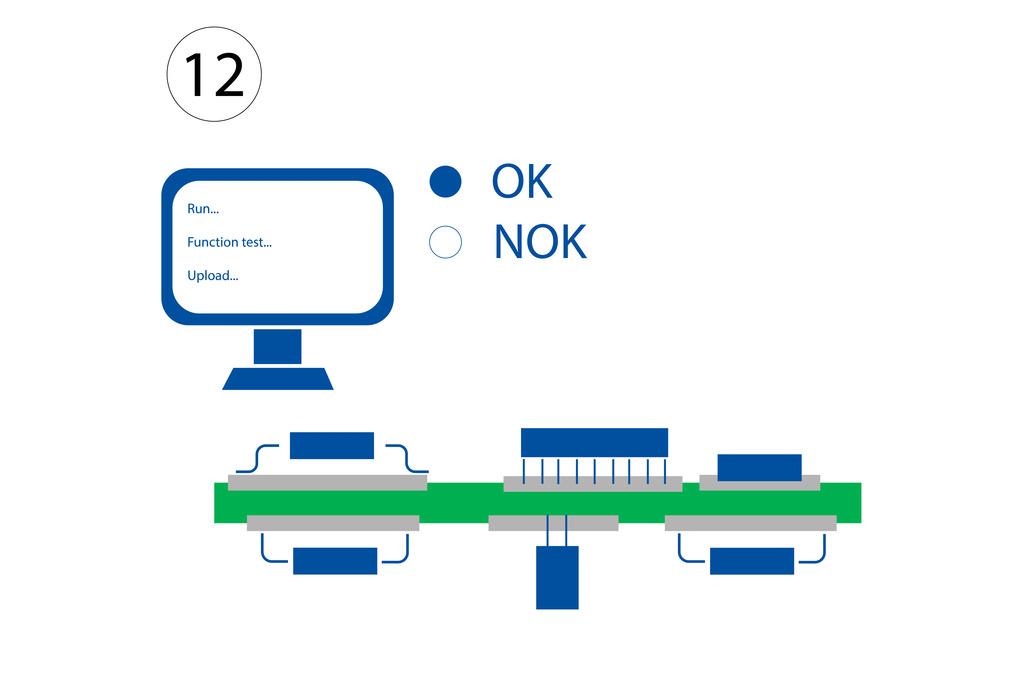

| 12 | Function test | ✓ | ✓ |

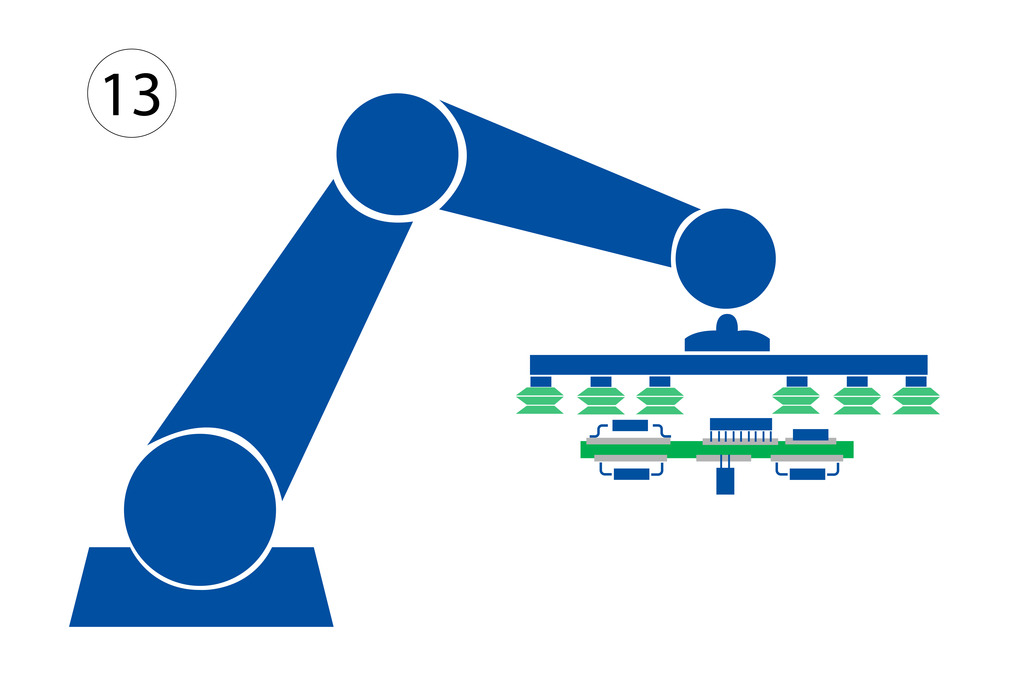

| 13 | Packaging | ✓ |

A wide range of technologies can be employed in the assembly of PCBs. By way of example, components can be connected to the PCB using through-hole technology (THT) or surface-mount technology (SMT). Depending on the application, both technologies can also be combined on a single PCB to reap the benefits of both mounting types.

The following provides more details on the individual process steps involved in the assembly of printed-circuit boards.

Diverse Applications of Vacuum Technology During PCB Assembly

Incoming Material Inspection and Initial Steps

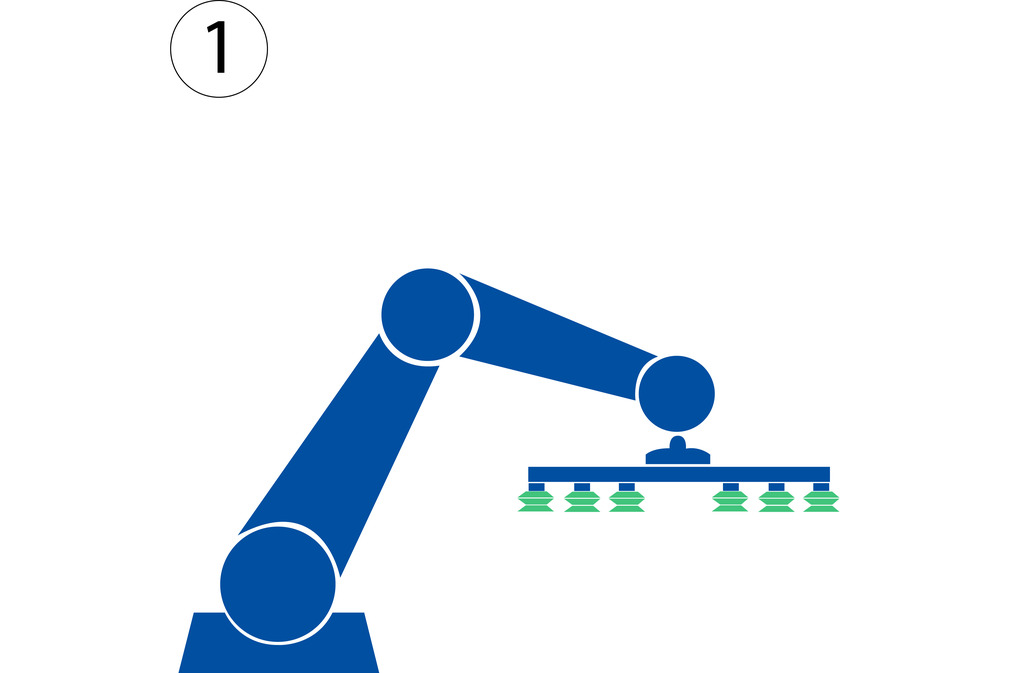

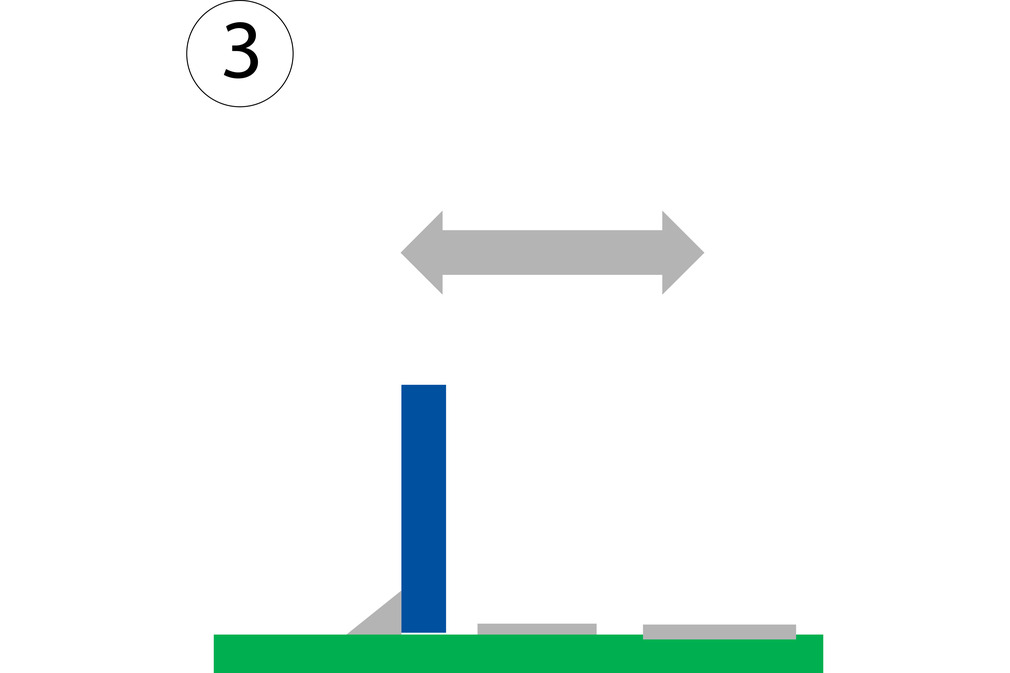

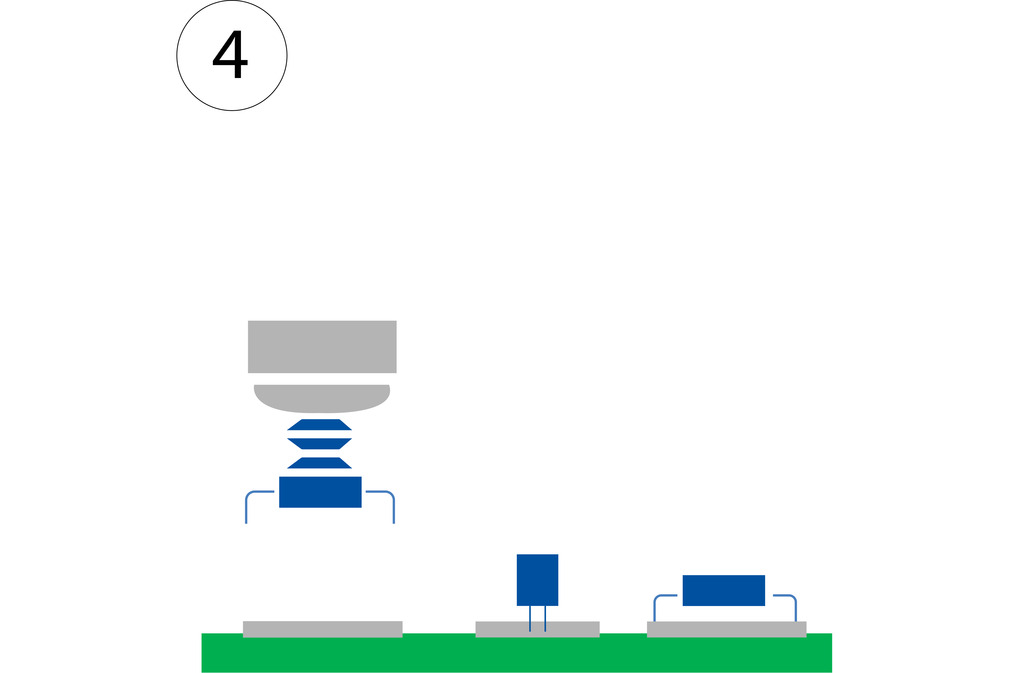

To begin with, the blank PCBs are taken to the in-line assembly lines (1). Before any subsequent processing takes place, an initial inspection is performed (2). Following the incoming inspection, the soldering paste is applied using a squeegee blade and a mask (3). After additional inspection steps, the components are positioned on the PCB (4).

Soldering the Components and Preparing the Reverse Side

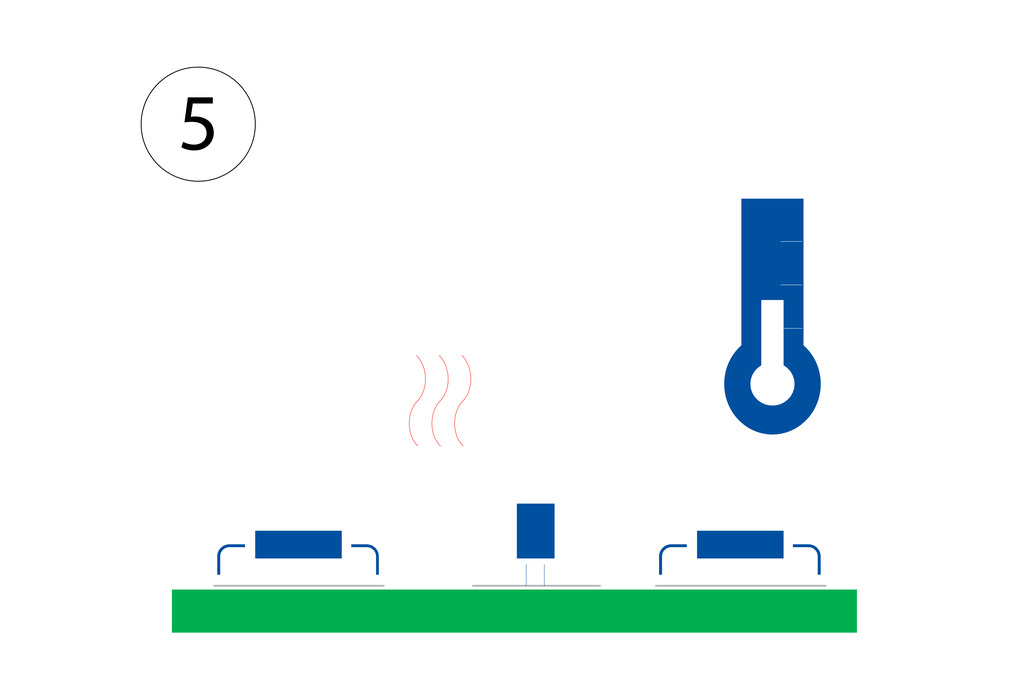

During the reflow soldering process (5), the PCB is heated such that the previously applied soldering paste melts. Following a further inspection (6), the part-assembled PCB is rotated (7) so that the second side can be assembled. As with the first side, the soldering paste is applied (8), visually examined and inspected for errors.

Assembling and Inspecting the Second Side

The reverse side of the PCB (9) is assembled in the same way as the previously assembled side. Different pick-and-place machines are required depending on the parts and components employed. The reflow procedure is once again used to connect the components to the PCB (10). The following inspection (11) and subsequent function test (12) are performed on the basis of custom test protocols for the specific board. The finished and inspected PCB is then prepared for transport (13).