- EFFICIENT

- EFFICIENT

Compact Terminals SCTSi IO-Link

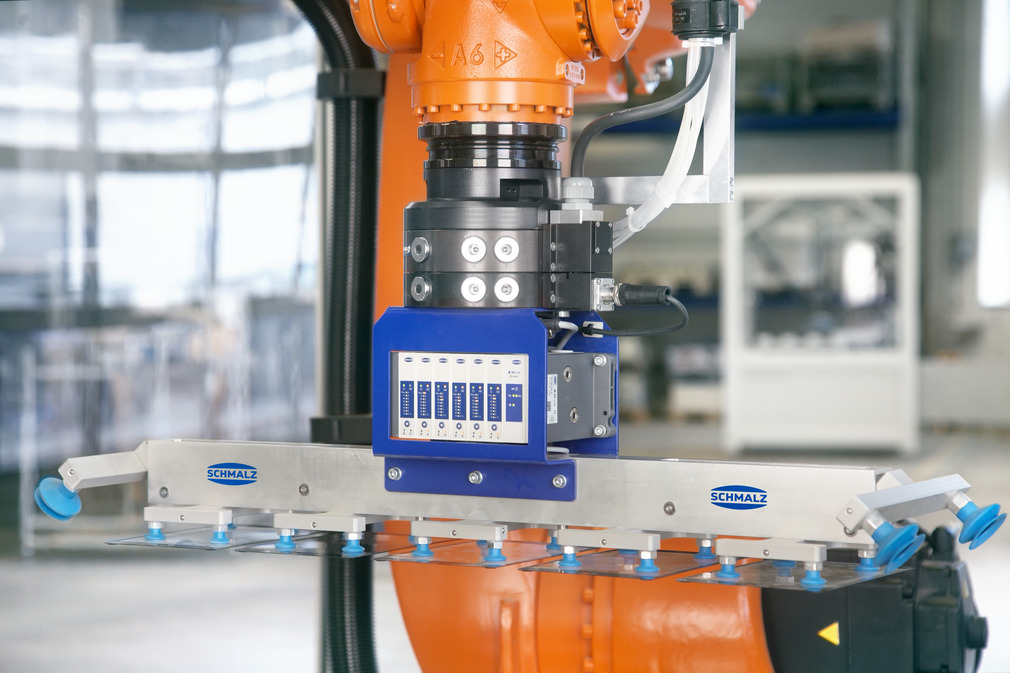

Flexible, Fully Networked Vacuum Generation

Variety, optimization of production processes, and continuous energy and process control are the challenges of the future. In order to meet these demands, powerful, flexible and energy-efficient vacuum systems are required. The answer is our Compact Terminal SCTSi IO-Link, a compact unit of several vacuum generators for simultaneously and independently handling different parts with a single vacuum system.

Central compressed air and power supply for up to 16 ejectors

Direct connection to the controller via only one data line

Modular design with different, individually controllable vacuum circuits for handling different workpieces

Easy configurability of process and device parameters via IO-Link or NFC

Reduction of compressed air consumption by up to 80 % thanks to automatic air saving function

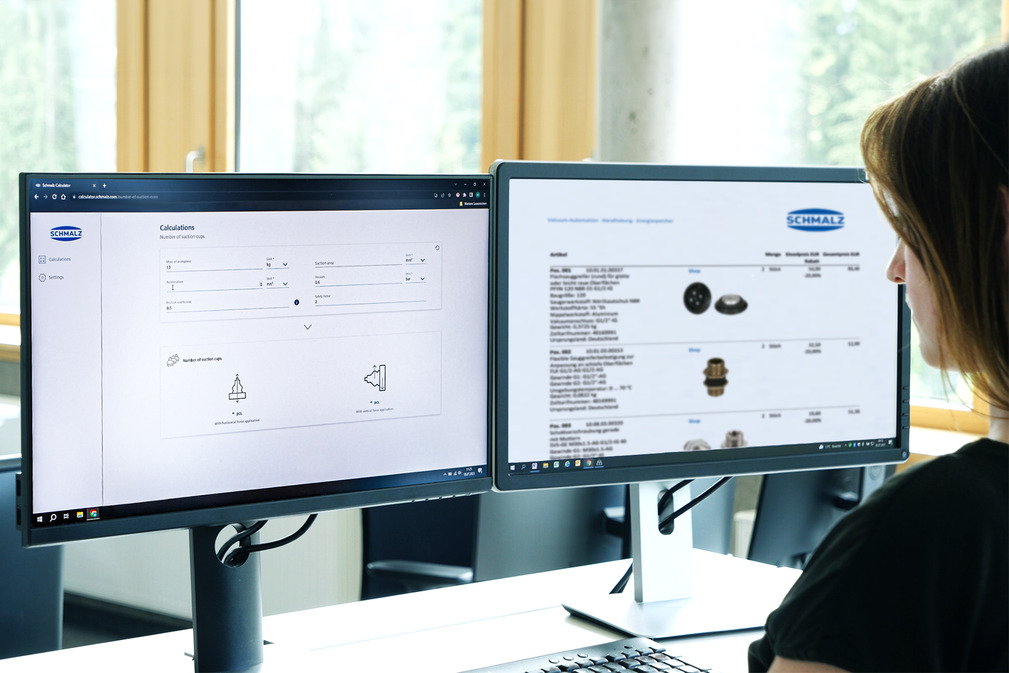

Your Individual Configuration

The compact terminals SCTSi offer the flexibility to design the handling process entirely according to your needs. Thanks to innovative configurators, our sales staff can create a custom-made solution for you in no time at all.

In addition to an offer for your individual product, you will also receive a CAD model.

Request your personal configuration now and contact us!

Design

.jpg)

- Lean and central compressed air supply (1)

- NFC chip (2) for reading and writing process information

- Central energy supply and IO-Link connection M12, 5-pin, using the control module (3)

- Vacuum connections (5) using threaded connectors

- Compact vacuum terminal consisting of up to 16 blocked compact ejectors (4)

Ordering information

Product code

Similar to a part number, the product code is used to uniquely identify product configurations at Schmalz. The product code can be found on the product label or on the quotation or order. Do you have questions about your product or would you like to order a configuration again? Then please have this key ready when you contact Schmalz.

| Code | Type |

|---|---|

| SCTSI | SCTSi |

| Code | Type |

|---|---|

| IOL | IO-Link |

| Code | Type |

|---|---|

| E + number | Number of ejectors |

| V + number | Number of valves |

| E + number V + number | Number of ejectors and number of valves |

| Code | Type |

|---|---|

| I + number | Number of IO-Link modules |

| D + number | Number of digital modules |

| I + number V + number | Number of IO-Link and digital modules |

| Code | Type |

|---|---|

| ABC00001C | Individual configuration code |

Ordering information

Main body

| Variant | Type |

|---|---|

| SCTSi-IOL | Main body SCTSi IO-Link |

Number of ejectors

| Variant | Type |

|---|---|

| 1-16 | Number of ejectors |

Note:

A number of 16 ejectors can be integrated in one terminal.

Terminal variant

| Variant | Type |

|---|---|

| AA | Standard version, push-in vacuum connection, hose outer diameter = 6 mm (for nozzle size = 0.7 mm and 1.0 mm) or hose outer diameter = 8 mm ( for nozzle size = 1.5 mm) |

| AB | Standard version, threaded connection G1/8"-F (for all nozzle sizes) |

Ejectors (example)

| Variant | Type | Option of terminal | Suction rate l/min | Air consumption l/min | Part no. |

|---|---|---|---|---|---|

| C8B | SCPst 07 GS01 NC C8B | AA | 16 | 22 | 10.02.02.05957 |

| C79 | SCPSt 07 GS01 NO C79 | AA | 16 | 22 | 10.02.02.05954 |

| C8N | SCPSt 10 GS01 NC C8N | AA | 36 | 46 | 10.02.02.05984 |

| C8A | SCPSt 10 GS01 NO C8A | AA | 36 | 46 | 10.02.02.05956 |

| C7U | SCPSt 15 GS02 NC C7U | AA | 65,5 | 98,5 | 10.02.02.06203 |

| C78 | SCPSt 15 GS02 NO C78 | AA | 65,5 | 98,5 | 10.02.02.06202 |

| C7E | SCPSt 07 G02 NC C7E | AB | 16 | 22 | 10.02.02.06187 |

| C7H | SCPSt 07 G02 NO C7H | AB | 16 | 22 | 10.02.02.06184 |

| C7D | SCPSt 10 G02 NC C7D | AB | 36 | 46 | 10.02.02.06188 |

| C7B | SCPSt 10 G02 NO C7B | AB | 36 | 46 | 10.02.02.06185 |

| C7N | SCPSt 15 G02 NC C7N | AB | 65,5 | 98,5 | 10.02.02.06189 |

| C7A | SCPSt 15 G02 NO C7A | AB | 65,5 | 98,5 | 10.02.02.06186 |

Note:

You can choose between different nozzle Technologies and sizes, connections or rest positions for the suction Valve (NO/NC/IMP).

A maximum of 4 different ejector blocks are possible.

From 9 ejectors upwards, a larger hose Diameter is required for compressed air supply.

Technical Data

Technical Data Compact Terminal SCTSi IO-Link (Electronics)

| Type | Operating temperature [°C] |

Pressure range (operating pressure) [bar] |

Electrical connection | Communication |

|---|---|---|---|---|

| SCTSi IO-Link | 0...50 | 2...6 | M12, 5-pin plug | IO-Link class B |

Technical Data Compact Ejectors SCPSt

| Type | Nozzle Size [mm] |

Degree of evacuation [%]* |

Max. suction rate [m³/h]* |

Max. suction rate [l/min]* |

Vacuum air consumption [m³/h]* |

Air consumption for blow off [m³/h]* |

Sound level free* [dB(A)]** |

Sound level during gripping* [dB(A)]** |

|---|---|---|---|---|---|---|---|---|

| SCPSt 07... | 07 | 85 | 0.98 | 16.0 | 1.35 | 7.25 | 63 | 58 |

| SCPSt 10... | 10 | 85 | 2.21 | 36.0 | 2.85 | 7.25 | 73 | 60 |

| SCPSt 15... | 15 | 85 | 4.03 | 65.5 | 6.03 | 7.25 | 73 | 65 |

| SCPSt 2-07... | 2-07 | 85 | 2.28 | 37.0 | 1.35 | 7.25 | 63 | 58 |

| SCPSt 2-09... | 2-09 | 85 | 3.05 | 49.5 | 2.49 | 7.25 | 73 | 60 |

| SCPSt 2-14... | 2-14 | 85 | 4.40 | 71.5 | 5.04 | 7.25 | 75 | 65 |

*At optimal operating pressure (4 bar)

**No linear increase in sound level with increase in ejector disks

Performance Data

| 0 | 50 | 100 | 150 | 200 | 250 | 300 | 400 | 500 | 600 | 700 | 800 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.7 mm | 0.01 | 0.15 | 0.31 | 0.48 | 0.67 | 0.91 | 1.19 | 1.85 | 2.72 | 4.00 | 6.07 | 10.50 |

| 2-0.7 mm | 0.00 | 0.00 | 0.00 | 0.08 | 0.15 | 0.35 | 0.40 | 0.85 | 1.75 | 2.70 | 4.20 | 7.20 |

| 0 | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.7 mm | 15.69 | 13.56 | 12.28 | 11.22 | 10.37 | 9.36 | 8.21 | 7.38 | 6.22 | 4.83 | 4.05 | 3.00 | 2.11 | 1.69 | 1.16 | 0.63 | 0.25 |

| 2-0.7 mm | 37.20 | 32.30 | 28.10 | 24.00 | 19.90 | 16.50 | 12.50 | 10.00 | 7.50 | 5.40 | 3.90 | 3.10 | 2.00 | 1.60 | 1.00 | 0.63 | 0.30 |

| 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|

| 0.7 mm | 477.81 | 700.18 | 867.18 | 855.86 | 838.29 |

| 2-0.7 mm | 334.00 | 564.57 | 789.19 | 892.20 | 885.26 |

| 0 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | |

|---|---|---|---|---|---|---|---|---|---|

| 1.0 mm | 0.00 | 0.15 | 0.30 | 0.50 | 0.80 | 1.20 | 1.75 | 2.80 | 5.50 |

| 2-0.9 mm | 0.00 | 0.00 | 0.00 | 0.20 | 0.45 | 0.85 | 1.45 | 2.50 | 5.00 |

| 0 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | |

|---|---|---|---|---|---|---|---|---|---|

| 1.5 mm | 0.00 | 0.07 | 0.15 | 0.25 | 0.40 | 0.60 | 0.90 | 1.30 | 2.30 |

| 2-1.4 mm | 0.00 | 0.00 | 0.00 | 0.10 | 0.20 | 0.35 | 0.65 | 1.20 | 2.30 |

| 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|

| 1.0 mm | 475.00 | 700.00 | 850.00 | 850.00 | 810.00 |

| 2-0.9 mm | 430.00 | 650.00 | 820.00 | 875.00 | 860.00 |

| 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|

| 1.5 mm | 450.00 | 660.00 | 870.00 | 880.00 | 865.00 |

| 2-1.4 mm | 390.00 | 590.00 | 800.00 | 890.00 | 880.00 |

| 0 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | |

|---|---|---|---|---|---|---|---|---|---|

| 1.5 mm | 65.50 | 57.10 | 47.40 | 39.30 | 32.00 | 25.30 | 17.00 | 8.80 | 1.50 |

| 2-1.4 mm | 71.80 | 61.40 | 52.50 | 42.20 | 31.90 | 23.50 | 15.30 | 8.50 | 1.20 |

| 0 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | |

|---|---|---|---|---|---|---|---|---|---|

| 1.0 mm | 36.10 | 29.50 | 25.90 | 20.80 | 16.90 | 13.00 | 8.10 | 3.40 | 0.50 |

| 2-0.9 mm | 49.60 | 42.10 | 34.40 | 24.70 | 17.00 | 11.60 | 7.20 | 3.30 | 0.50 |

Documentation

The matching documentation for this product is available in this section.

| Documents | Language |

|---|---|

| English | |

| English | |

| English |

Software

The matching software for this product is available in this section.

| Software | Language |

|---|---|

| English | |

| English |

Functional descriptions

.jpg)

Near-Field Communication (NFC)

- Reliable communication via an energy-neutral point-to-point connection

- Visible data – Both statistical data (such as the serial number) and dynamic process data (such as switching points) can be read out

- Parameterization option – An app can be used to parameterize the SCTSi IO-Link directly from a smartphone

.jpg)

Networking in Industry 4.0 Systems

- The IO-Link connection means that recorded data can be viewed and used all the way up to the control level, which allows for bidirectional parameterization and diagnostics in all conventional field-bus systems

- Condition monitoring increases system availability by providing detailed analyses of the system’s condition and early detection of faults

- Predictive maintenance improves the performance of gripping systems

- Energy monitoring optimizes the vacuum system's energy consumption

.jpg)

Automatic Air Saving Function

- Switches off the suction function once a safe vacuum value has been reached until the next cycle or until the vacuum falls below the safe vacuum value

- Various configuration values and air saving settings can be programmed separately for each ejector

- Reduction of compressed air consumption by up to 80 %

.jpg)

Integrated Electronic Sub-Bus System

- Electronic control can be implemented with just a single cable

- Comprehensive data communication via IO-Link and near-field communication (NFC)

- All ejectors can be separately programmed and controlled

Eco-Nozzle Technology

- Eco-nozzle technology provides a considerably higher suction rate with minimized compressed air consumption for energy-efficient vacuum generation

Integration

Simplified Integration in the Control Level

(1) Connection of SCTSI via IO-Link master

(2) Connection SCTSi via Profinet / EtherCAT / Ethernet/IP

Products

- EFFICIENT

- EFFICIENT

- EFFICIENT

.jpg)