- Wide range of spare and wear parts

- Vacuum generation, lifting hoses, protective hoses, etc

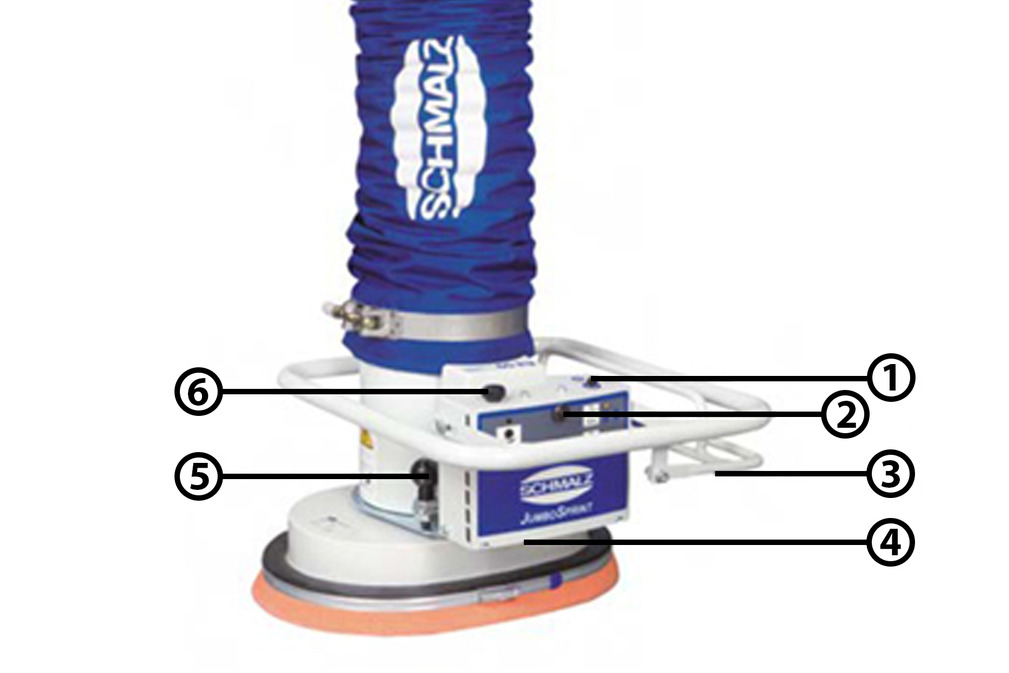

Vacuum Tube Lifters JumboSprint

For compact workpieces weighing up to 300 kg

The JumboSprint is equipped with a bow-shaped operator handle which extends all the way around the unit. This allows the user to optimally position it on compact goods such as bags or rubber bales. The load is raised by pulling up on the handle lever and lowered by pushing down.

All around operator handle for optimal transfer of force and guidance of the device

Modular design and extensive gripper and accessories program for implementing individual requirements

Increases employee motivation and minimizes work-related musculoskeletal disorders

Optional rotation unit for continuously rotating and precisely positioning workpieces up to 200 kg

Handling by only one person

Together for greater sustainability - with Jumbos in action.

Our innovative vacuum technology combines sustainability with economic success. Thanks to intelligent system optimization, you can save up to 90 % of your energy consumption with the new Eco function, depending on the application. This not only makes a valuable contribution to environmental protection, but also significantly improves your ROI.

Find out more now and discover new ways to lift your vacuum tube lifter to the next level.

Modular system

(1) Radio remote control SRC for vacuum generator (optional)

(2) Filter - changable without tools

(3) Bow-shaped Operator handle for Lifting, lowering and releasing the load

(4) Suspension height can be adjusted without the load attached

(5) Quick-change adapter for vacuum grippers (optional)

(6) Suspension height can be adjusted with a load attached

Modular elements

Quick-change adapter

Versatility is key: Schmalz offers the right suction cups for virtually any application. With quick-change adapter the gripper can be changed quickly and easily.

.jpg)

Single vacuum gripper

For compact goods such as cardboard boxes, barrels, buckets, jugs and cabinets.

.jpg)

Single vacuum gripper, long

For pallets, narrow cardboard boxes, beams, square tubes and other elongated workpieces.

.jpg)

Round vacuum gripper

For barrels, buckets or stone slabs with rough surfaces.

.jpg)

Double vacuum gripper

For cardboard boxes, crates or sheets. The vacuum grippers can be continuously adjusted along the beam.

Double vacuum gripper FMP

For pallets, sections or cut pieces where the vacuum gripper is not fully covered by the workpiece. The grippers can be continuously adjusted along the beam.

Quadruple vacuum gripper

For large cardboard boxes, sheets and non-rigid pieces. The vacuum grippers can be continuously adjusted lengthwise and crossways.

.jpg)

Multiple vacuum gripper

For uneven workpieces such as foil trays or unstable cardboard boxes. The individual vacuum grippers optimally compensate for any unevenness.

Sack gripper

For handling suction tight or porous paper, plastics and fabric bags.

Technical Data

The vacuum tube lifters JumboErgo and JumboSprint can be configured specifically based on the requirements of each individual application due to their modular design. The technical data varies depending on the configuration and on the vacuum gripper chosen.

The following technical data are standard values.

| Type | Workpiece format* Min [mm] |

Workpiece format* Max [mm] |

Operator handle length L [mm] |

Max. lifting speed [m/min] |

Max. lifting stroke Z [mm] |

Height H** [mm] |

|---|---|---|---|---|---|---|

| JumboErgo | 300x200 | 4,000x2,000 | 350-1,000 | 60 | 1,700 | 2,850 |

| 300x200 | 4,000x2,000 | 350-1,000 | 60 | 2,100 | 3,400 | |

| JumboSprint | 300x200 | 3,000x1,000 | 155-500 | 60 | 1,700 | 2,850 |

| 300x200 | 3,000x1,000 | 155-500 | 60 | 2,100 | 3,400 |

A lift capacity of 140 kg and higher applies: lifting stroke Z +160 mm, height H +250 mm

*Depends on the vacuum gripper chosen

**Vacuum gripper not included (total height = H + height of the vacuum gripper)

Lift Capacities

| Jumbo type | Max. lift capacity [kg] | Ø Lift tube | |

|---|---|---|---|

| Horizontal | 90° swivel | D [mm] | |

| Ergo/Sprint 35 | 35 | - | 120 |

| Ergo/Sprint 45 | 45 | 30 | 140 |

| Ergo/Sprint 65 | 65 | 50 | 160 |

| Ergo/Sprint 85 | 85 | 70 | 178 |

| Ergo/Sprint 110 | 110 | 90 | 203 |

| Ergo/Sprint 140 | 140 | 120 | 230 |

| Ergo/Sprint 200 | 200 | - | 250 |

| Ergo/Sprint 300 | 300 | - | 305 |

Handling systems for the Chinese market

The product area of handling systems is covered in China by our experienced partner Binar Handling. With this cooperation, we ensure that our high standards for quality, efficiency and service are also met in China.

If you require support or further information, please feel free to contact Binar Handling directly.

.jpg)

.jpg)