Suction cup material HT1-ESD

Sensitive electronics perfectly handled – minimized marks, maximized ESD protection

Through minimized marks during handling

Due to ESD protection

Up to 170 °C

Sensitive electronics perfectly handled – minimized marks, maximized ESD protection

Through minimized marks during handling

Due to ESD protection

Up to 170 °C

There are no second chances in electronics manufacturing. One tiny mark, one electrostatic discharge and entire batches are unusable. Not with us! Our suction cups offer handling with minimized marks, optimum ESD protection and outstanding temperature resistance.

One minute with our industry segment manager

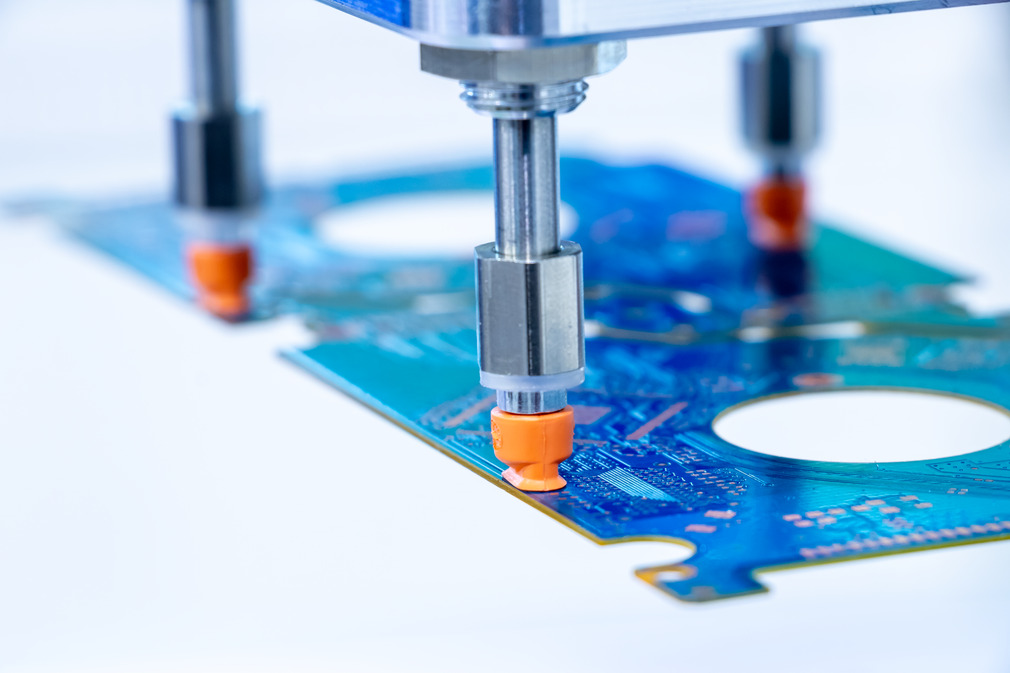

The suction cups made of the material HT1-ESD accompany every handling process in the production of final products, consumer electronics and home appliances – from complex end devices such as printed-circuit boards in cell phones to household appliances such as refrigerators.

Schmalz stands for technological excellence in Vacuum Automation – and for innovation that begins in the detail: in the material. As a technology leader, we don't just develop intelligent automation solutions, we also develop the materials that make these solutions possible. Our material technology is unique: from recipe development through systematic testing to series production – everything is done in-house. State-of-the-art production technology and strictly defined quality standards are used to create high-performance suction cups precisely tailored to your requirements, making your processes safer, more efficient and more sustainable. The result: materials such as HT1-ESD that are exactly matched to your requirements – developed, tested and produced to the highest standards.

Need to optimize handling in electronics production? With our suction cups made from the new material HT1-ESD, we are setting new standards for handling processes in the production of final products, consumer electronics and home appliances.

The material offers permanent ESD protection, enables handling with minimized marks and has good resistance to high temperatures and ozone, without any critical additives or coatings that could diffuse into production environments and generate harmful particles.

Receive up to 20 free test samples for your system – including personal on-site consultation.

The innovative suction cup material HT1-ESD combines the proven materials HT1 and NBR-ESD for maximum efficiency and uncompromising quality. This allows us to make optimum use of the advantages of both established materials and set new standards for handling sensitive components.

The suction cups made of the new material HT1-ESD are available in different shapes to suit the variety of workpieces and use cases.

With our own material development and state-of-the-art technology, we set new standards to meet your individual requirements.

HT1-ESD is an innovative suction cup material that combines the proven advantages of the already established materials HT1 (high-temperature resistance, minimized marks) and NBR-ESD (ESD protection without additional conductive carbon black). Unlike conventional alternatives, suction cups made of the material HT1-ESD deliver optimal electrostatic discharge protection, eliminate unwanted marking, and maintain temperature resistance up to 170 °C – without compromising on the quality of the suction cup. This ensures that the surfaces of your components remain clean and no damage is caused. Developed specifically for demanding electronics and glass manufacturing, the material HT1-ESD sets new standards in service life.

Many conventional suction cups with ESD protection use conductive carbon black to control electrostatic discharges. The problem: carbon black particles can detach with wear, causing contamination and loss of yield. In addition, suction cups with conductive additives can run the risk of unpredictable resistance variance.

The material HT1-ESD is completely free of conductive carbon black and instead uses dissipative material compositions (resistance range 10⁶-10⁹ Ω), which ensure safe potential equalization – without particle emission.

Temperature resistant up to 170 °C. Our suction cups retain their mechanical and chemical properties without damage, cracks or material degradation even at high temperatures during short-term processes. This makes them ideal for high-temperature processes such as lamination, testing of electronic components or other thermally demanding production steps.

The temperature resistance of the suction cups depends on the suction cup wall thickness and the environmental influences.

It is a dissipative material with a specific resistance range of 10⁶ to 10⁹ Ω. Voltages applied to the workpiece are discharged in a controlled and damage-free way – without sudden discharges that could damage sensitive components. In contrast to coated solutions, the ESD performance remains constant over the entire service life.

The material HT1-ESD has been specially developed for handling with leaving minimized marks. Thanks to minimized chemical residues, surfaces remain clean – particularly important for display glasses, semiconductors and high-quality electronic components. This significantly reduces rejects and post-processing operations.

The material HT1-ESD impresses with its high ozone resistance and wear resistance, which significantly extends the service life of the suction cups. This means less maintenance, less downtime and lower operating costs. This pays off, especially in 24/7 production environments.

The material HT1-ESD is ideal for all handling processes in electronics manufacturing, including

Wherever ESD protection, high-temperature conditions and protection from unwanted marks are critical.

Yes, suction cups made of the material HT1-ESD are available in various shapes and can be integrated into existing vacuum gripper systems. Our experts will be happy to help you select the right suction cups for your specific application.

Yes, suction cups made of the material HT1-ESD are available in different shapes – from flat vacuum suction cups for large substrates to small, flexible suction cups for complex geometries. This is how we cover the variety of workpieces in electronics production.

Conventional coated ESD suction cups have a problem: the coating can flake off, which impairs flexibility and ESD performance. Suction cups made from the material HT1-ESD are uncoated – the material itself is dissipative. This means

✅ No detachment of coatings

✅ Constant ESD performance over the entire lifetime

✅ Higher reliability and less risk of failure

Choose the material HT1-ESD if you want to combine all the advantages:

In short: The material HT1-ESD is the best choice if you don't want to compromise in electronics manufacturing.

Automation solutions with suction cups made of the material HT1-ESD reduce costs on several levels:

✅ Fewer rejects thanks to handling that leaves less marks and offers ESD protection

✅ Longer service life reduces replacement and maintenance costs

✅ Less downtime thanks to high reliability

✅ Reduced risk of contamination saves rework and increases yield

Because Schmalz carries out the entire process in-house, from material development with formulation development and systematic test procedures to series production. This enables maximum reliability and precision for your requirements. Our specially developed materials such as HT1-ESD are precisely tailored to the high requirements of handling sensitive components. The result: high-performance suction cups that make your processes safer, more efficient and more sustainable – with guaranteed quality standards worldwide.

We have summarized the most important information for you in a free webinar. Simply request it using our form – and skip straight to the chapters that are relevant to your requirements.